DESIGN &

OPTIMISATION

Using cutting-edge simulation tools, we engineer the perfect balance of strength, weight, and cost, analysing every detail to ensure our designs are as efficient as they are effective.

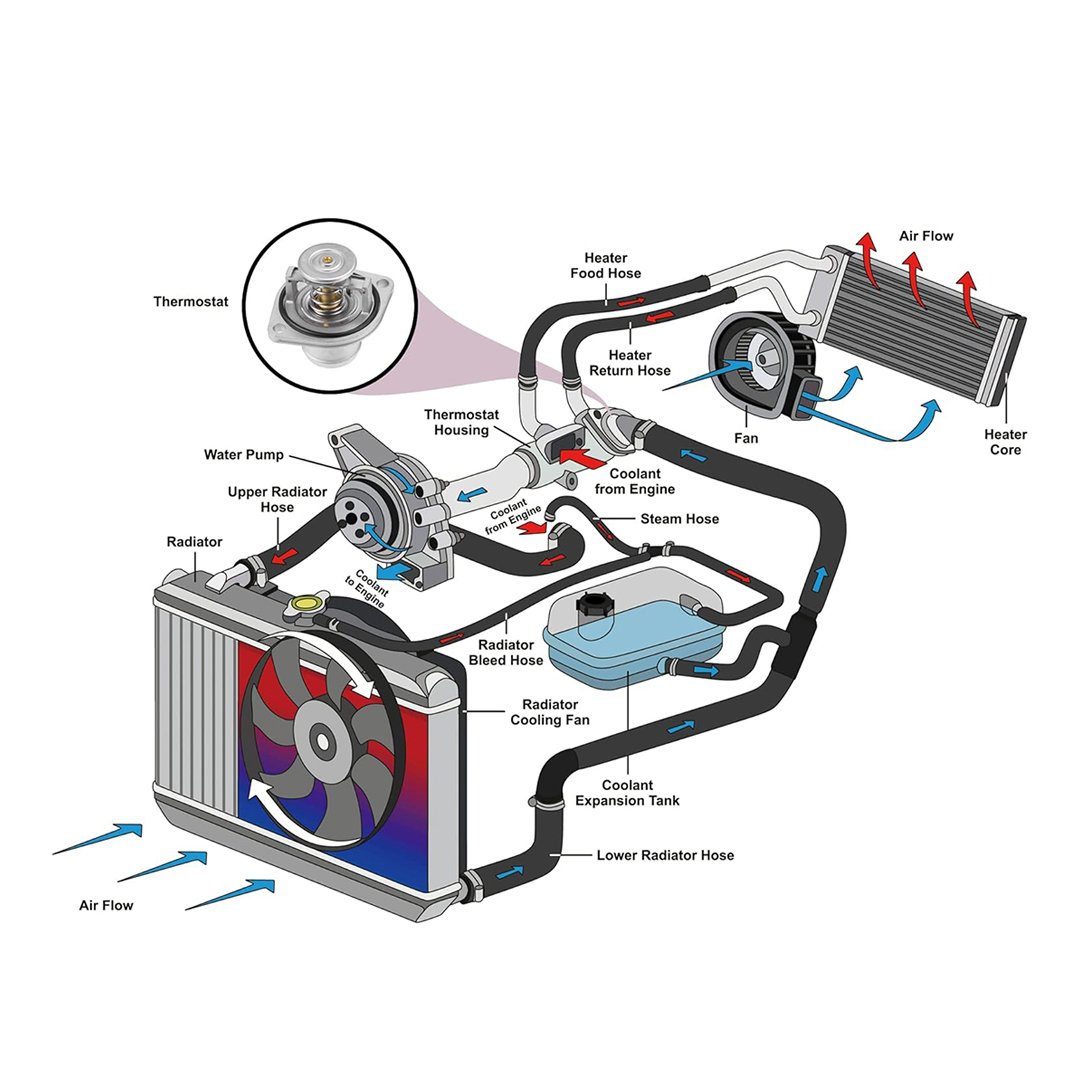

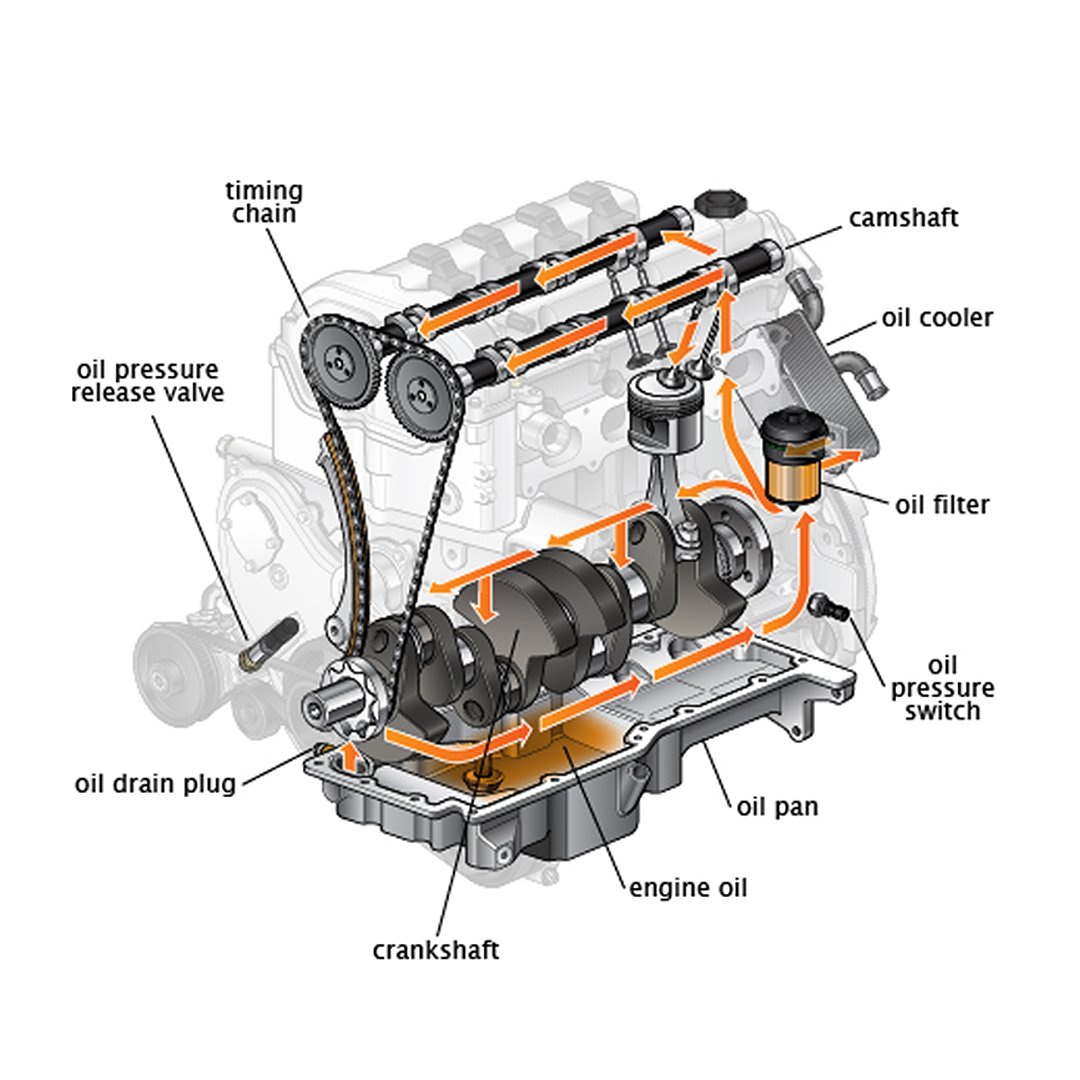

We develop components within mechanical systems to work in harmony and perform in the harshest conditions.

Our expertise lies in crafting solutions for environments involving elevated temperatures, high mechanical loads and prolonged duty cycles, ensuring durability and performance where it matters most.

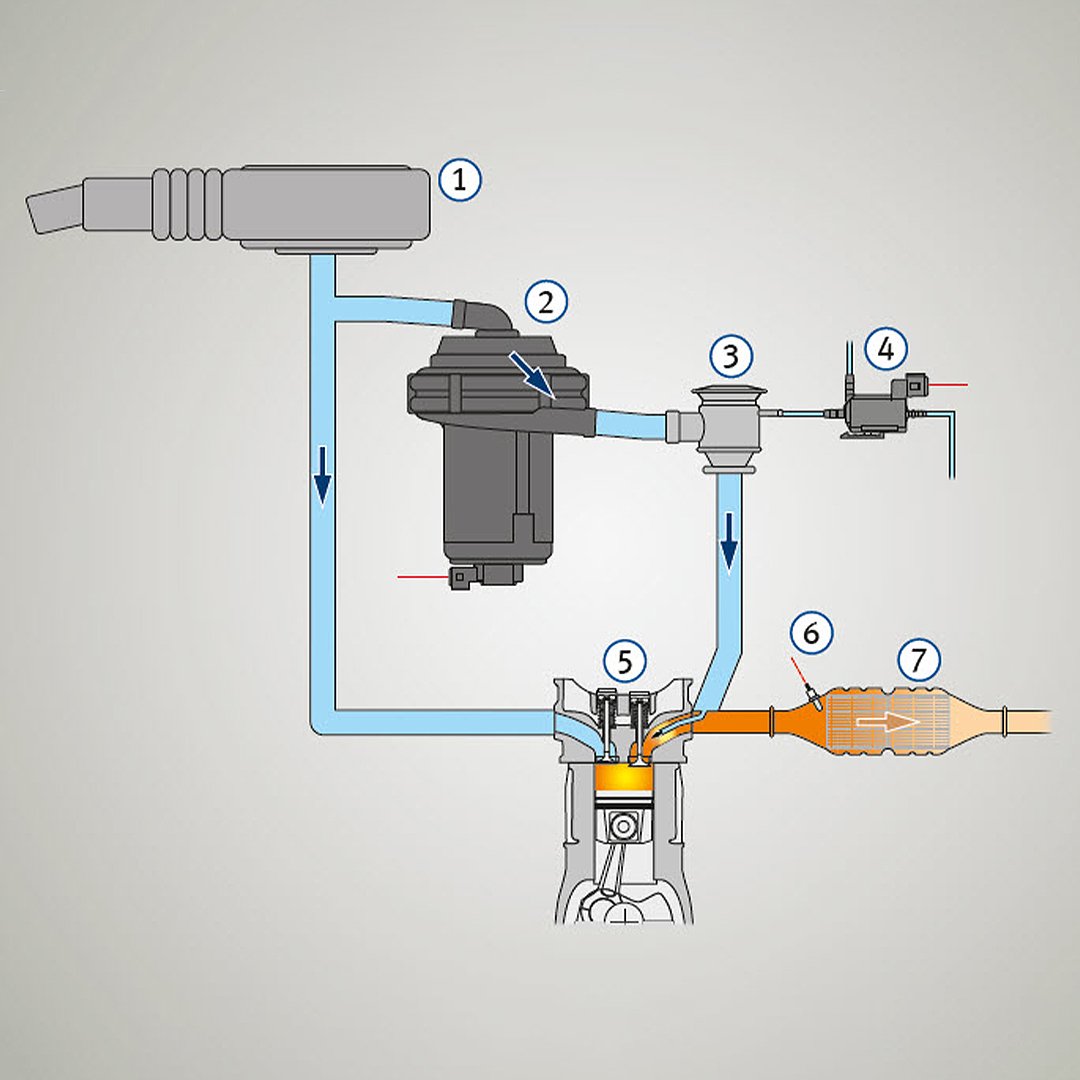

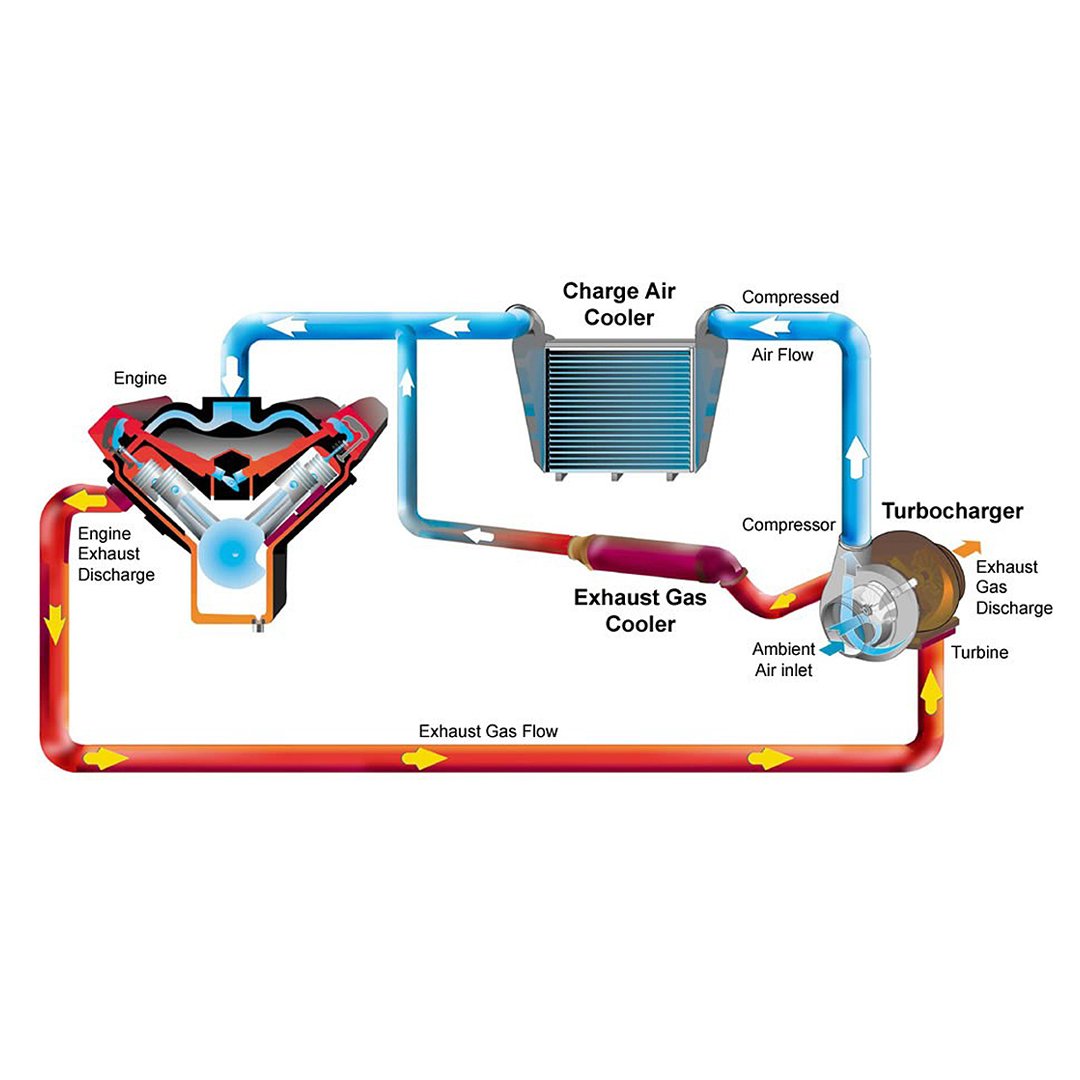

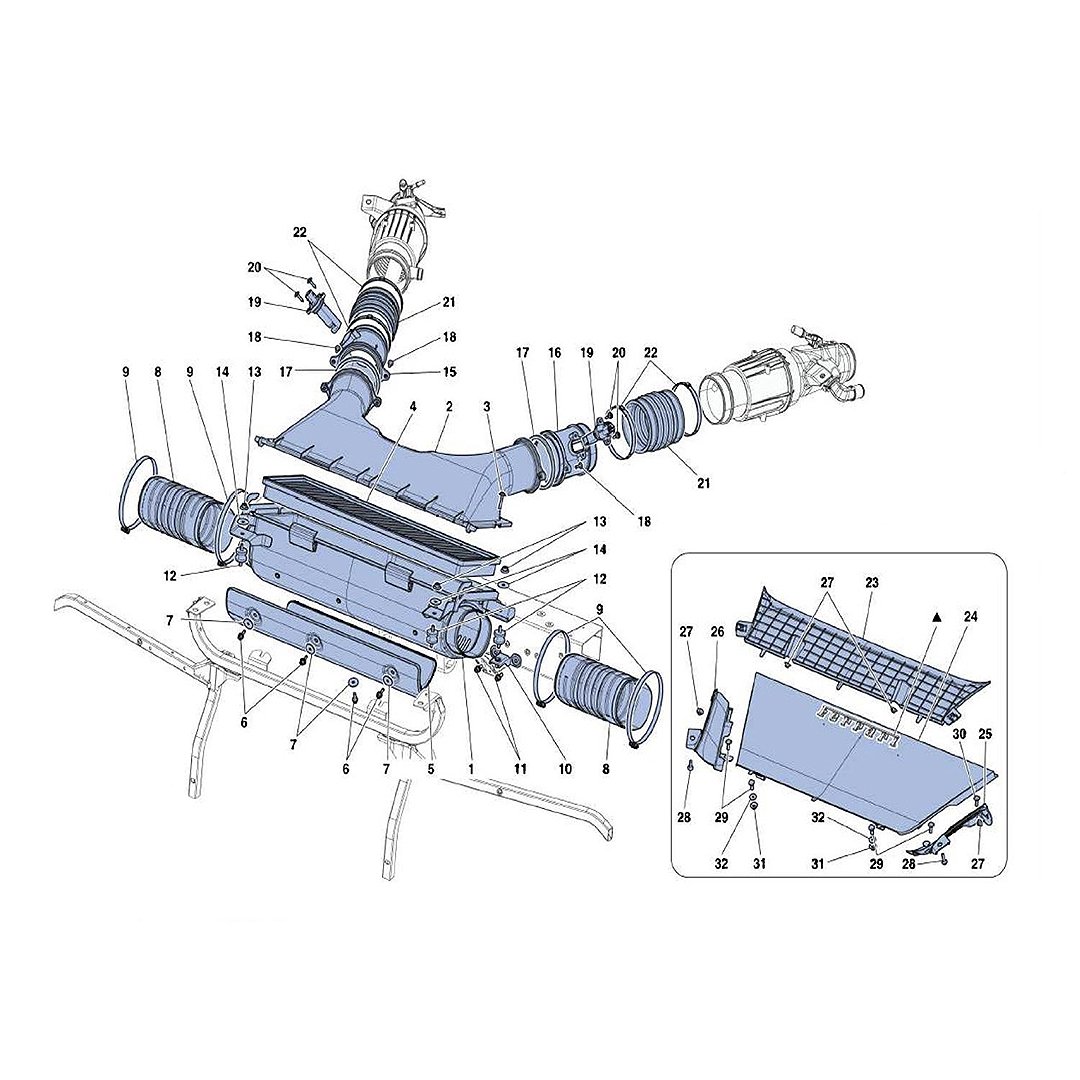

In modern powertrain architectures, where electronic and mechanical systems converge, we work closely with leading manufacturers to integrate these technologies into cohesive, full vehicle solutions that meet the highest of standards.

Examples of these include:

We understand the requirements of such systems and the essential collaboration with other disciplines during their development in order for them to function correctly.

Tools which we utilise to aid in the development of these components include:

3D

MODELLING

3D modelling is a cornerstone of contemporary manufacturing and engineering, and we integrate it into every project to facilitate clear communication across all stakeholders, including; clients, suppliers, and production teams.

Our commitment to precision ensures that both our 3D models and accompanying 2D drawings are crafted with meticulous attention to detail. This rigorous approach minimises the risk of miscommunication or data loss during design translation and interpretation, resulting in smoother workflows and more reliable outcomes.

Finite Element

Analysis (FEA)

This is a powerful simulation technique we employ to identify regions of elevated stress concentration within components or structures. By leveraging this predictive capability early in the design process, we can optimise and refine geometries prior to physical manufacturing, significantly reducing the risk of prototype failures during testing.

This approach not only streamlines development timelines and lowers costs but also offers valuable insights into material selection, helping ensure that each application is matched with the most suitable material for performance and durability.

Computational Fluid Dynamics (CFD)

We employ sophisticated fluid flow simulation and visualisation techniques to enhance the performance of complex systems.

This approach is particularly valuable in applications such as combustion engine intake and exhaust systems, as well as heat exchangers. By analysing key parameters, including; pressure drop, heat rejection, flow reversal and eddy current formation, we tailor solutions to meet specific system requirements, ensuring optimal efficiency and functionality.

Structural Topology Optimisation

Structural topology optimisation is a powerful design methodology that strategically reduces componentmass while preserving essential strength and stiffness.

Although traditionally underutilised in the motor vehicle industry, largely due to the complex geometries it often produces, this technique proves exceptionally effective for high-performance, low-volume applications. When light weighting is critical and manufacturing constraints are more flexible, topology optimisation offers a transformative advantage in engineering design.

These tools are constantly evolving and provide more opportunities and advanced insights into the characteristics of a products’ design and manufacturing techniques.

3D

Modelling

Read More

Our commitment to precision ensures that both our 3D models and accompanying 2D drawings are crafted with meticulous attention to detail. This rigorous approach minimises the risk of miscommunication or data loss during design translation and interpretation, resulting in smoother workflows and more reliable outcomes.

Finite Element Analysis (FEA)

Read More

This approach not only streamlines development timelines and lowers costs but also offers valuable insights into material selection, helping ensure that each application is matched with the most suitable material for performance and durability.

Computational Fluid Dynamics (CFD)

We employ sophisticated fluid flow simulation and visualisation techniques to enhance the performance of complex systems.

Read More

This approach is particularly valuable in applications such as combustion engine intake and exhaust systems, as well as heat exchangers. By analysing key parameters, including; pressure drop, heat rejection, flow reversal and eddy current formation, we tailor solutions to meet specific system requirements, ensuring optimal efficiency and functionality.

Structural Topology Optimisation

Structural topology optimisation is a powerful design methodology that strategically reduces component mass while preserving essential strength and stiffness.

Read More

Although traditionally underutilised in the motor vehicle industry, largely due to the complex geometries it often produces, this technique proves exceptionally effective for high-performance, low-volume applications. When light weighting is critical and manufacturing constraints are more flexible, topology optimisation offers a transformative advantage in engineering design.

These tools are constantly evolving and provide more opportunities and advanced insights into the characteristics of a products’ design and manufacturing techniques.

What are your Design needs?

Ready to perfect your mechanical system? Talk to our team about your design and optimisation needs today.