Images courtesy of MANNER Sensortelemetrie GmbH

PISTON TEMPERATURE MEASUREMENT

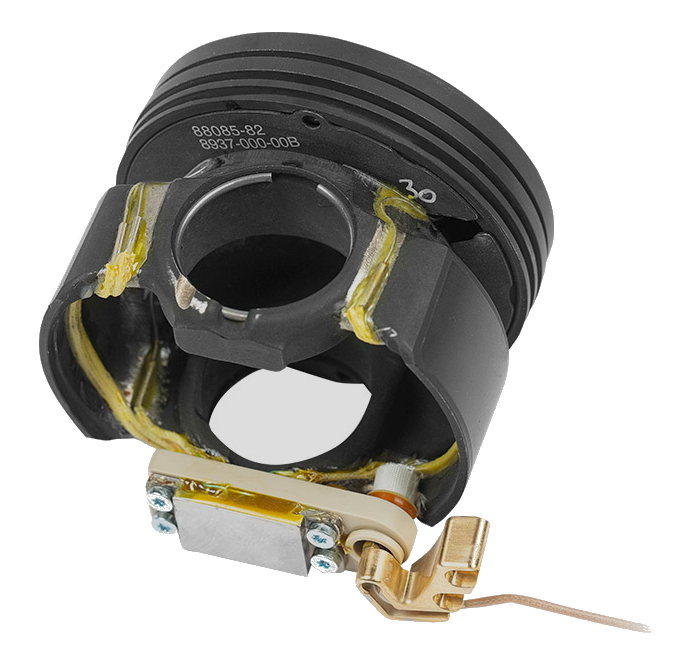

A project we worked on for a high performance engine development company involved designing a bespoke piston able to accommodate the fixing of an amplifier and wireless transmitter to the underside, along with the installation of thermocouples in specific locations on the crown of the piston.

This piston also required a corresponding receiver fitted to the piston cooling jet in order to communicate with the transmitter when the piston was at bottom-dead-centre.

The purpose to this kit was to allow real-time temperature measurements to be recorded from designated regions of the piston on a running engine, capable of over 10,000RPM.

This provided valuable data for feeding back into the simulation loop for optimising the performance and structural geometry of production pistons.

LINEAR ACTUATED STERNDRIVE

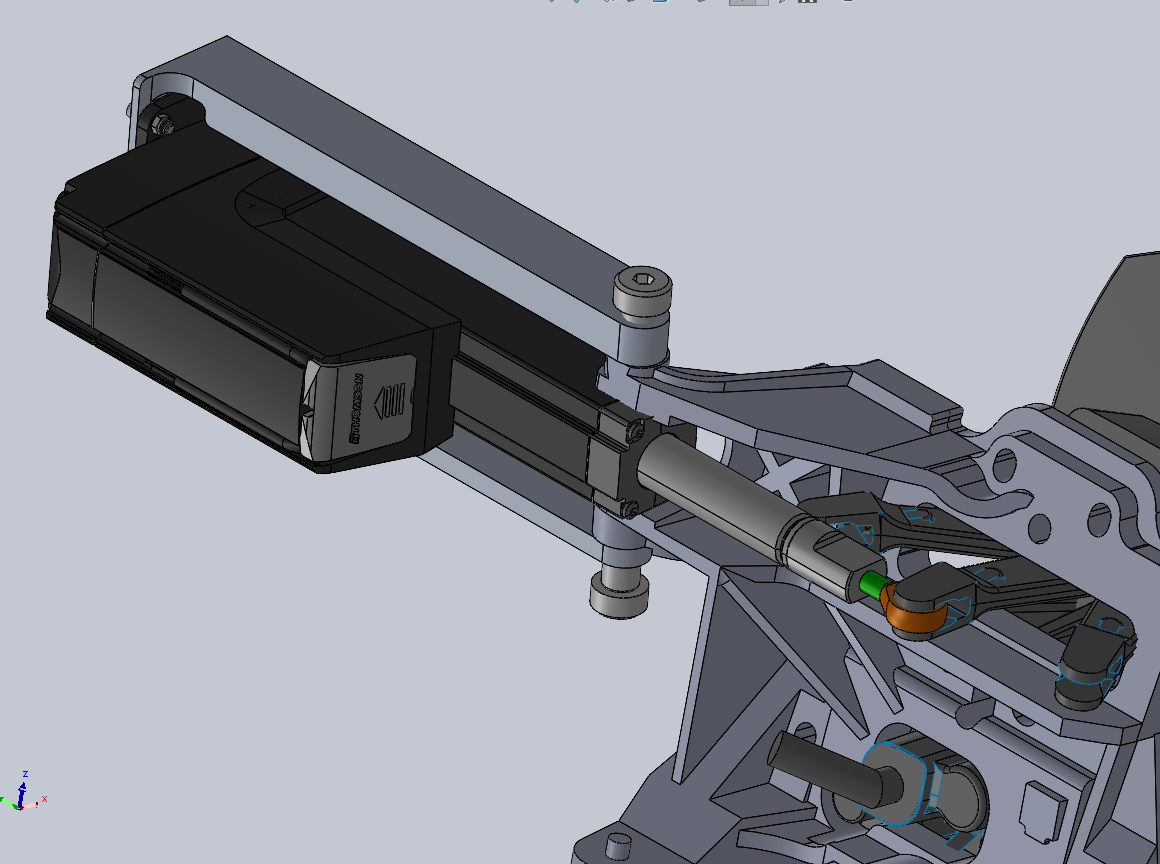

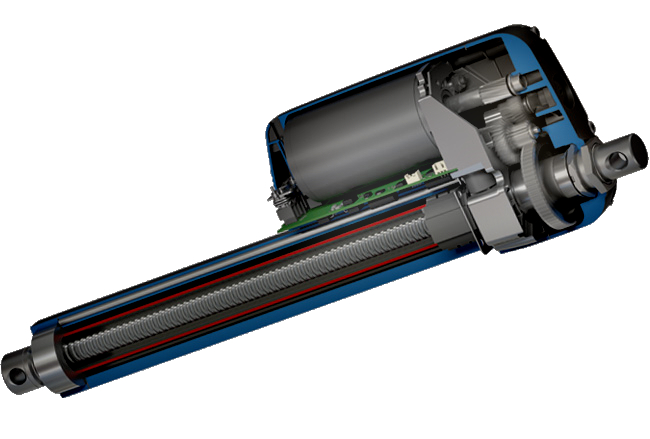

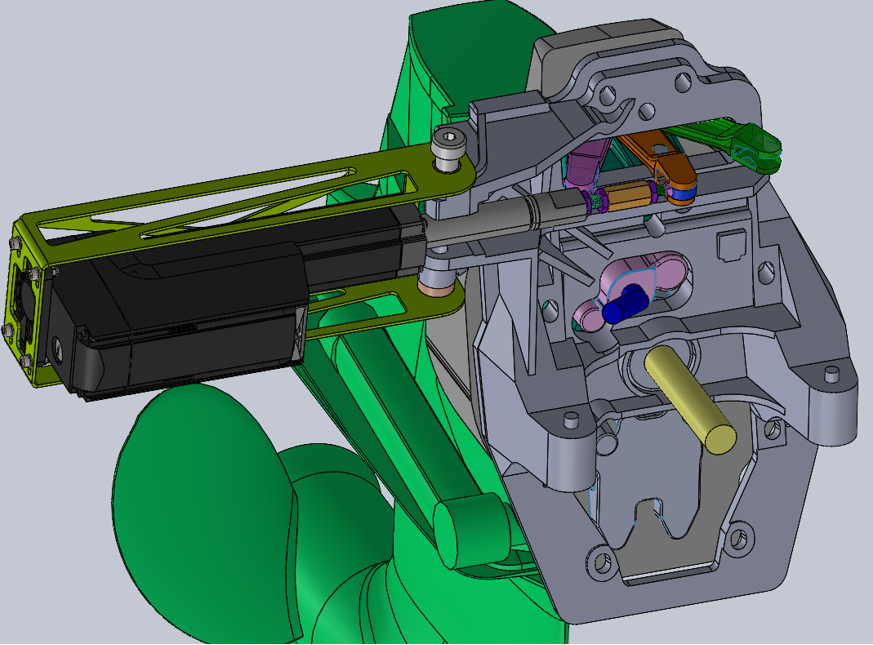

Some of the work we have carried out for the marine industry includes a transom mounted stern drive linear actuator assembly required for an electric powerboat being manufactured in the south of France.

We collaborated with the engineering team developing this new vessel to ensure the stern drive system met the functional performance requirements along with the battery compartment emergency ventilation system and helmsman display panel.

TRIUMPH BOBBER PASSENGER SEAT

A small project we worked on for Thornton Hundred Motorcycles to help develop their Pillion Seat for the Triumph Bobber.

They decided to do backflips off the bike, they were that happy!

GORDON MURRAY AUTOMOTIVE – ‘GEORGE’

Always great to see the test driver of a prototype vehicle talking about how he kept laughing at the incredible sound of this machine.

Converting an Ultima kit car to accommodate a prototype V12 engine and its matching six-speed transmission is our bread-and-butter.

750 FORMULA – LIGHTWEIGHT FLYWHEEL

There is nothing we love more than to optimise the performance of a product, and this 750 Formula racing Flywheel was a perfect candidate for such an activity.

As with any development project, we started with the rulebook for the Championship that this product is intended to be used in, giving us the boundary conditions for us to work within for the design.

We recognised that there is an opportunity to optimise the rotational inertia of the Flywheel and reduce it’s mass to less than 3.5kg, providing the original part markings were maintained, as stipulated in the regulations.

Through a careful process of reverse engineering, rig testing and finite element analysis, an optimised design was defined.

This resulted in a 52% reduction in total mass, and a 58% reduction in rotational inertia.

These improvements translate into greater throttle response, reduced vehicle mass and lower starter motor engagement torque.

VOLUME MEASURING DISH

This is a product we are very excited about.

From years of lessons learnt in the automotive and motorsport industry, we have developed this tool to radically improve the repeatability, ease-of-operation, time and accuracy of a very unique process carried out during the build of a combustion engine.

Using a simple, yet effective, vacuum pressure in a sealed cavity, this tool provides a hassle-free method of providing a closed chamber for the internal volume to be measured.