POWERTRAIN ARCHITECTURE

We engineer the core architecture of drivetrains for both automotive and motorsportapplications.

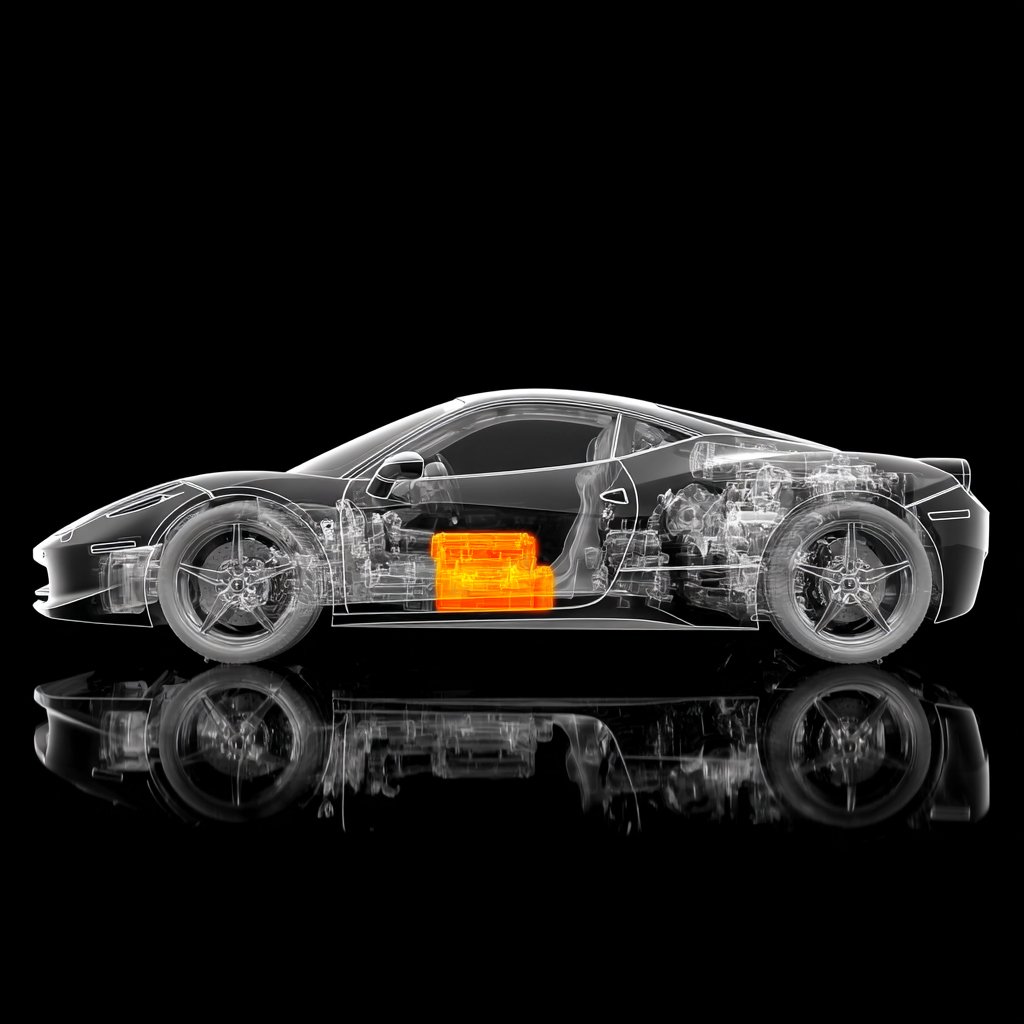

INTERNAL COMBUSTION

The design of an internal combustion engine (ICE) powertrain begins with defining the overall concept layout and system architecture, which are critical to meeting performance, efficiency, and packaging goals. At this stage, we determine the engine configuration, such as; inline, V-type or flat, as well as the number of cylinders and displacement, which directly influence the engine’s balance, size, and power characteristics. The layout must also consider how the engine integrates with the transmission system, whether this is manual, automatic, or continuously variable unit, and how torque is delivered to the drive wheels. The packaging of these elements within the vehicle’s chassis requires close coordination between mechanical and thermal systems to ensure optimal weight distribution, cooling, and serviceability. Ultimately, the powertrain architecture serves as the foundation upon which performance targets, emissions compliance, and vehicle dynamics are built.

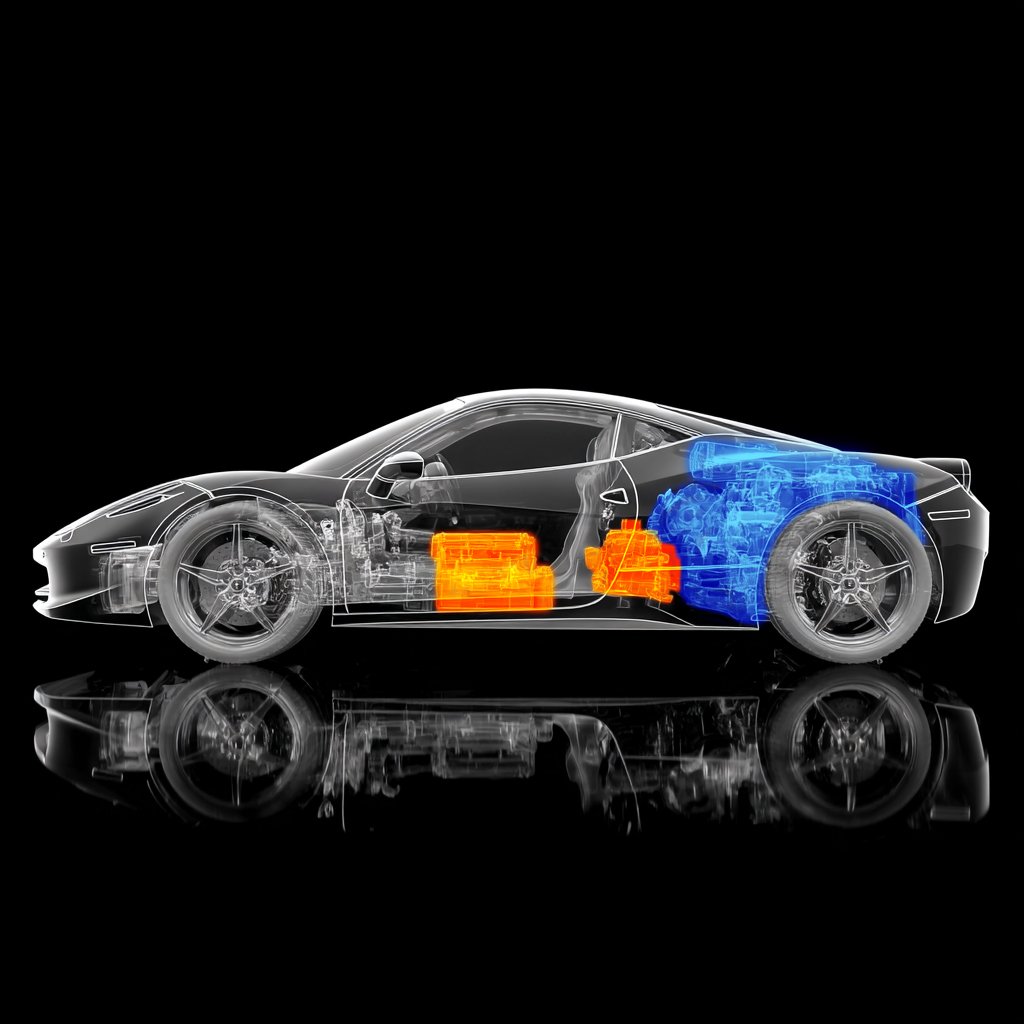

ELECTRIC

HYBRID

What are your Powertrain needs?

What powertrain do you need? Talk to one of our engineers today.